What We Do

Omar Coffee Solar PV

Topping out at just below 100kW, this fixed-tilt solar installation at Omar Coffee provides 100% of the annual energy needs for this facility in Newington CT. Ravex and sister Phalcon company PowerHawke, provided the turnkey project including utility interconnection coordination, permitting and development, solar and site engineering, and installation of this roof mounted Solar PV system.

Amazon HQ2

This regionally ‘prized’ 2,800,000 square foot project for Amazon’s Virgina headquarters utilizes every aspect of our expansive expertise – wireless and wired motion sensors, daylight harvesting, power sensing for emergency lighting, power distribution and emergency systems, main fire alarm networked control with over 3,000 addressable devices and over 3,500 notification devices two way communication systems. The project scope included core & shell and interior fit-out of two 22-story office buildings, retail space for 14 businesses and 2.5 acres of public space. Prefabrication was utilized as a key method of maintaining the tight schedule and controlling the quality of the built-out systems. At its peak, Phalcon resources on this project topped more than 350 electrical tradespeople and 50 project and design professionals.

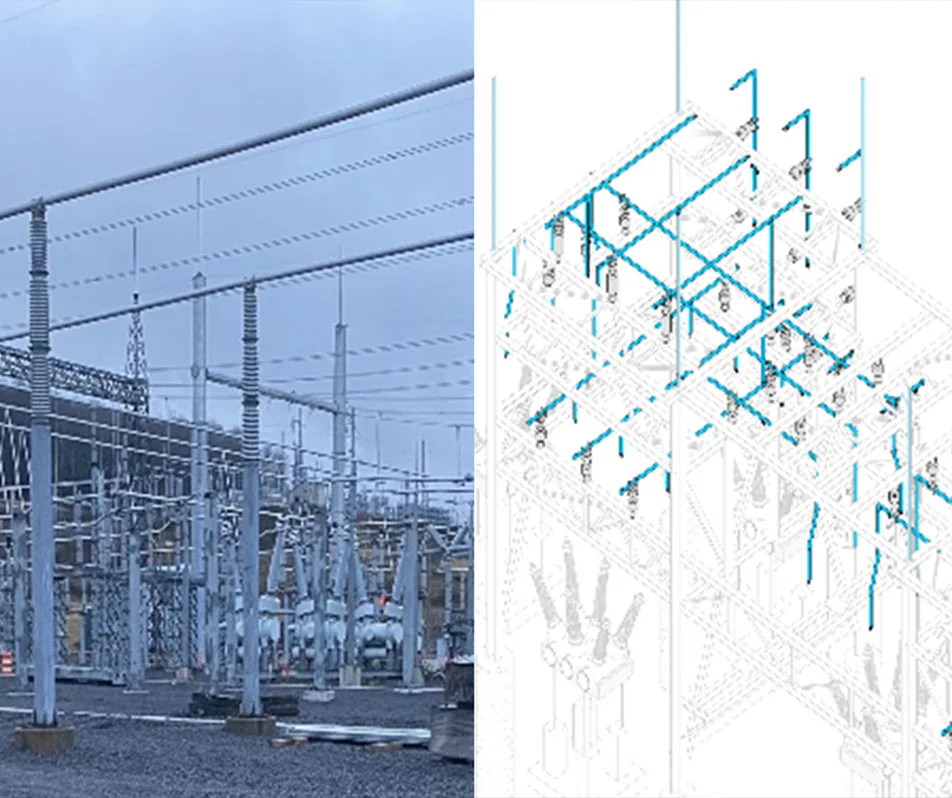

115kV-345kV Substation Prefab

The expansion of an existing substation, an additional 115kV substation yard and upgrades to an existing 345kV substation yard framed the scope of this project to meet future demands and reliability requirements of the upstate NY region. Design and prefabrication of welded 115kV and 345kV buss was completed off site in a climate-controlled environment and shipped to the site after rigorous QA/QC parameters were met. The elimination of field welding alone resulted in more than a 20% reduction in field labor while assuring almost zero rework.

Mustang Prefab

This 60MW datacenter facility is a massive technology warehouse used to host IT operations and houses some of the most complex technology in the world. Through its expertise in BIM and coordination, PowerHawke partnered with sister company JE Richards to prefab over 75% of all install electrical infrastructure for this project in their 100,000 sq ft, state -of-the-art Lanham, MD prefabrication facility. Detailed assembly drawings and fabrication sequencing was developed to produce a high quality deliverable within an extreme installation schedule.

BIM Modelling

Utilizing todays industry leading Autodesk Revit platform, PowerHawke is leading the way for it’s sister companies and industry partners in Design, BIM, Coordination and Prefab. Enhancements with innovative design approaches, custom Revit families and cutting edge software applications brings down field cycle time and increases productivity and QA/QC in highly competitive installation projects. Coup[led with decades of field experience, PowerHawke is self-performing BIM for some of today’s most complex and demanding electrical installation projects.

Arc Flash Risk Assessment

For more than a decade, PowerHawke has been providing turnkey Arc Flash Risk Assessments in accordance with NFPA 70, Standard for Electrical Safety in the Workplace. Our approach covers all field data collection, modelling, analysis, field labeling and reporting along with hazard risk mitigation strategies based on unique results at each site. Our field engineers travel across the Phalcon operating footprint to deliver these technical services alongside our sister company operations.

Why

PowerHawke?

Our team of building modeling engineers tackle today’s most complex electrical systems across commercial, industrial, and utility sectors. Our expertise in Building Information Modeling (BIM) using industry tools like Revit, Dynamo and Navisworks lend a competitive edge to our operating companies. Always striving to push the envelope, our BIM team is integral to our successful prefabrication operations across the Phalcon footprint enabling the collective expertise of Phalcon for any customer, location, or project.

CONTACT POWERHAWKE

Whether you would like to discuss your next project or to express interest in working as part of our team, contact us and we’ll be happy to get back to you right away. Or if you have other questions, let us know how we can help you.

OFFICE LOCATION:

CONNECTICUT OFFICE

132 Scott Swamp Road

Farmington, CT 06032

860.606.0065